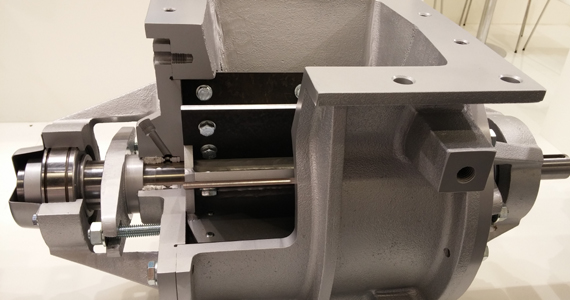

ROTARY VALVE

When performing transfer on all pneumatic lines, it is a device to feed the material down to the line and separate the raw material pneumatically transferred from the air. Blade forms, tolerances, revolution speeds vary depending on type of process and type of the product to be transported. Likewise, it may a

prosesS

At DOSERAY, our products provide “Perfectly Matched Performance”

for your dry processing, powder and bulk solids applications.

With DOSERAY’s extensive line of

equipment and systems, you will obtain the best possible results

of your process time after time. Each of our high-quality

products are developed to serve each industry differently, in

order to provide the desired outcome of each processing

application.

Each of our products carries the

DOSERAY guarantee of efficiency and

durability, while designed to adapt to serve the needs of a

variety of industry applications. DOSERAY products are rugged

and time-tested, providing the best results for materials

processing. Whether you plan to feed, size, enlarge, weigh, or

reduce your material, DOSERAY products

provide the DOSERAY Management Solutions you seek.

PRODUCTS

ScREW CONVEYOR

Screw conveyors move materials either horizontally, on an incline or vertically. They are used to feed, distribute, collect or mix and can be equipped to either heat or cool while performing this transfer. With the proper cover and gasketing, they are easily made dust or weather tight and rodent proof. Their clean compact design saves valuable space since no return run is required. Screw Conveyors fit in cramped quarters, are simple to support and easy to install . . . and they cost less than most other types of conveyors.

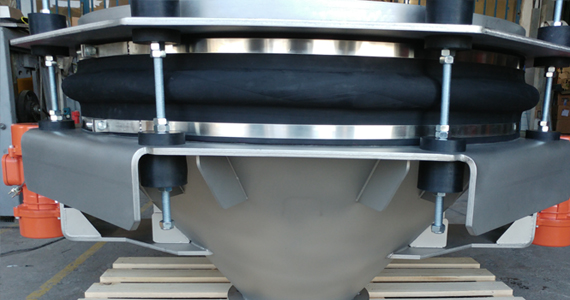

BIN DISCHARGER

PROCESS

Durability: Our Bin Activators are built to last with an average

of over 10 years of productive use. Their production availability

exceeds 95%.

• Optimal Flow plus Conserved Head Room: Our engineers

have deliberately designed a uniform 45-60 degree

side wall slope steep enough to ensure flow while Still conserving head

room.

• Internal Baffles: We have purposely provided more internal

baffles to prevent any bridging at the outlet of the Bin Activator.

- Label:rotary valve, bin activators, airlock, penumatic conveying, screw conveyor, bin discharger